F & FBA Series Panel Heaters

Quartz composite is the standard face on the F-Series panel heater, our best selling model.

F and FBA Series Face Options

Quartz composite is the standard face on the F-Series panel heater, our best selling model. It is produced by a patented process that uses a high temperature material and special cement to bond quartz fabric with a ceramic fiber coil support. The end result is a unique, highly durable, quartz composite face heater.

The F-Series heater has a tremendous amount of flexibility. Its shape can be manufactured rectangular (most common), square, round or C-shaped. The heat can be aimed in a single direction (most common) or in dual directions. Our special designs can help avoid cold spots across wide web applications. The maximum watt density of 25 watts/in2 (39 kW/m2) provides a sufficient amount of power for most applications. The use of an external reflector in most infrared heaters results in a dramatic loss of radiant efficiency over time. Because the proven design of the F-Series heater requires no external reflector, it maintains a consistently high radiant efficiency over time.

The F-Series heater is used in most process heating applications. The only applications where it might not be used are vacuum applications and those in which materials could possibly damage the heater’s face. Otherwise, this is the perfect heater for nearly all infrared heating, drying and curing applications.

F-Series Specifications

The F-Series heater can be constructed as wide as 30″ (762 mm) and as long as 84″ (2133 mm), though not that width and length in the same heater. For example, an 84″ (2133 mm) long heater is commonly 12″ (305 mm) wide. This heater is very flexible in size and watt density options. It has a maximum watt density of 25 watts/in2(39 kW/m2) and a durability defined by a typical life expectancy of 25,000 hours. The heater has a high radiant efficiency of 78.5%. Because its design does not depend on an external reflector, the heater maintains a high radiant efficiency over time. The F-Series heat transfer rate for 25 watts/in2(39 kW/m2) is 2.4 Btu/ft2/sec. delivered to the product and for 12.5 watts/in2 (19.4 kW/m2) is 1.15 Btu/ft2./sec. delivered to the product.

FBA-Series Specifications

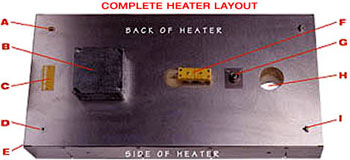

The FBA model has holes drilled in its face to enable forced air to flow through the heater. The airflow’s purpose is either to protect sensitive material or components from being damaged by infrared heating, improving the drying process by gently sweeping moisture away or by providing an infrared/convection heating combination. As an extension of the F-Series heater, the FBA model is manufactured with either 1/8″ (3.2 mm) or 1/4″ (6.4 mm) holes usually located 1″ (25.4 mm) from the center.

The heater has no internal insulation to accommodate a 2″-5″ (50.8-127 mm) typical plenum area in its cavity. It commonly has a back-mounted 3″ (76.2 mm) hole for airflow. The hole size can match your specifications. Smaller heaters have one hole, whereas larger heaters can have multiple holes. The airflow can also be directed through the side or end of the heater casing in some applications. Individual high-temperature fans can be attached directly to these holes, or a centrifugal fan can be used with ductwork to supply the air to multiple heaters. The airflow construction commonly has 20 to 50 cfm/ft2. Applications for the FBA model include removing moisture, operation in a secondary stage powder coating oven, screen printing and electronics.

The FBA-Series heater can be constructed as wide as 24″ (610 mm) and as long as 72″ (1829 mm), though not that width and length in the same heater. A 72″ (1829 mm) long heater is commonly 12″ (305 mm) wide. The heater has a maximum watt density of 25 watts/in2(39 kW/m2) and a durability defined by a typical life expectancy of 25,000 hours. It has a high radiant efficiency of 78.5%. Because the heater’s design does not depend on an external reflector, the heater maintains a consistently high radiant efficiency over time.

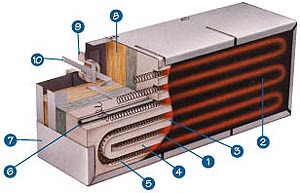

F-Series Panel Heater (Models: FB & FBA)

Heaters in the F-Series line of infared panel heaters have a very durable emitter surface constructed using a patented manufacturing process. The FB model has a solid flat uniform surface. Because the FBA heater has air holes drilled throughout its face, its insulation is removed to accommodate an air delivery plenum.

Features:

- High-temperature quartz cloth

- High-temperature black coating

- High-temperature cement bond

- Refractory board to hold resistance wire

- Precision resistance wire

- Quartz thermowell tube (optional)

- Heavy gauge aluminized steel frame

- Blanket insulation

- Ceramic bushings to insulate terminals

Stainless steel terminals

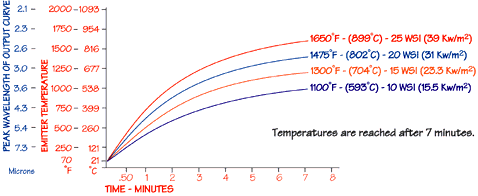

F-Series Warm-up Curve

The warm-up curves are measured from heaters running facedown in open air. The thermocouple is located in a standard location inside a thermowell behind the coil. The curves will change depending on the environment and thermocouple location.

- Construction Options

- Voltage, Phase, and Other Options

- Mounting Options

- Temperature Sensing Options

- Electrical Termination Options

Housing

The heater’s case or housing can be manufactured using aluminized steel or stainless steel. Additionally, in some cases the heater can be supplied without a case.

Aluminized steel is the most commonly used case material. It can achieve very high temperatures — namely 1200°F (649°C) — without flaking, discoloring, or degrading; this assures that the heater’s case will outlive the heater itself. The housing is typically riveted together. The rivets, along with slots in the heater case, permit controlled expansion and contraction during heat-up and cool-down processes. Some applications require the slots to be removed, which can be achieved for many engineering designs.

Stainless steel’s advantages of enhanced cleanliness and a very polished appearance make it a good choice for food and semiconductor applications. Because the 304 grade of stainless steel will discolor at a lower temperature than aluminized steel, the 310 grade of stainless steel is often chosen for extremely high temperature applications. A stainless steel case is usually riveted together in the same manner as aluminized steel though there are some applications where the stainless case is welded and polished for superior cleanliness and cosmetic appeal. Additionally, those housings are usually supplied without expansion slots. This construction is typically implemented in our glass, koramic and quartz face heaters.

The last option, called board only, is to have no case at all for the heater. This heater is usually an F-Series model without the housing, insulation or pre-constructed panel design. Customers who have in-house sheet metal capability will sometimes choose to buy the heating element, fiber board, quartz fabric and cement as a completed assembly. The remaining components of the panel fall under the customer’s responsibility. This approach shifts much of the heater’s construction and warranty issues toward the customer.

Standard Dimensions

| Width (mm) |

Length (mm) |

F | FBA | G | K | M | Q | ||||

| 6″ (152.4) |

12″ (304.8) |

18″ (457.2) |

24″ (609.6) |

30″ (762) |

36″ (914.4) |

X | X | X | X | X | |

| 6″ (152.4) |

42″ (1066.8) |

48″ (1219.2) |

54″ (1371.6) |

60″ (1524) |

X | X | X | X | |||

| 10″ (254) |

4″ (101.6) |

6″ (152.4) |

8″ (203.2) |

10″ (254) |

X | ||||||

| 12″ (304.8) |

6″ (152.4) |

10″ (254) |

12″ (304.8) |

X | |||||||

| 12″ (304.8) |

12″ (304.8) |

18″ (457.2) |

24″ (609.6) |

30″ (762) |

36″ (914.4) |

X | X | X | X | X | |

| 12″ (304.8) |

42″ (1066.8) |

48″ (1219.2) |

54″ (1371.6) |

60″ (1524) |

X | X | X | 42″ or 48″ |

|||

| 12″ (304.8) |

72″ (1828.8) |

84″ (2133.6) |

X | 72″ only |

|||||||

| 16″ (406.4) |

16″ (406.4) |

24″ (609.6) |

X | X | X | X | X | ||||

| 18″ (457.2) |

18″ (457.2) |

X | X | X | X | X | |||||

| 24″ (609.6) |

24″ (609.6) |

X | X | ||||||||

Note: Solar Products specializes in manufacturing custom heaters that match a specific application. Listed above are standard heater dimensions.

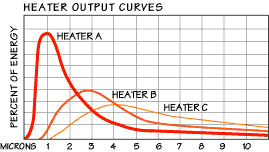

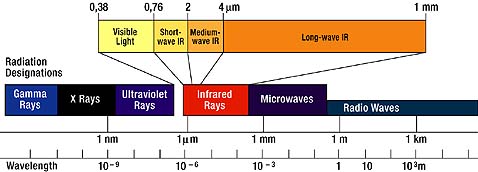

The wavelength output from our heaters ranges from 2.3 microns to 6 microns and is inversely proportional to heater temperature; that is to say, as the temperature increases the wavelength decreases. All heaters output energy over a range of wavelengths as depicted in the heater output curves appearing below.

The wavelength output from our heaters ranges from 2.3 microns to 6 microns and is inversely proportional to heater temperature; that is to say, as the temperature increases the wavelength decreases. All heaters output energy over a range of wavelengths as depicted in the heater output curves appearing below.

An end mount thermowell is the most common design. The thermowell is either a quartz tube (most common because of faster response) or ceramic tube located parallel to the heating element. The tube is typically 5″ (127mm) long and has an inner diameter of 0.157″ (4 mm). A thermocouple bracket is mounted outside the thermowell tube to assist in proper positioning and holding the thermocouple in place. The thermocouple is then located 4″ into the thermowell and fastened using the bracket. It is important to assure that the thermocouple is not over extended into the thermowell, which may result in incorrect temperature readings or heater failure. A thermocouple with a male plug is displayed.

An end mount thermowell is the most common design. The thermowell is either a quartz tube (most common because of faster response) or ceramic tube located parallel to the heating element. The tube is typically 5″ (127mm) long and has an inner diameter of 0.157″ (4 mm). A thermocouple bracket is mounted outside the thermowell tube to assist in proper positioning and holding the thermocouple in place. The thermocouple is then located 4″ into the thermowell and fastened using the bracket. It is important to assure that the thermocouple is not over extended into the thermowell, which may result in incorrect temperature readings or heater failure. A thermocouple with a male plug is displayed. The back mount design makes use of an L-shaped quartz tube that runs perpendicular to the coil toward the back of the heater. The thermowell then makes an arced 90° bend, continuing for a short distance parallel to the heating element. This design is used when the heaters are surrounded, not allowing side access, and requires the use of a .040″ (1 mm) diameter thermocouple in order to make the 90° bend. A thermocouple with a male/female plug combination is displayed. This design is not available for the Q-Series.

The back mount design makes use of an L-shaped quartz tube that runs perpendicular to the coil toward the back of the heater. The thermowell then makes an arced 90° bend, continuing for a short distance parallel to the heating element. This design is used when the heaters are surrounded, not allowing side access, and requires the use of a .040″ (1 mm) diameter thermocouple in order to make the 90° bend. A thermocouple with a male/female plug combination is displayed. This design is not available for the Q-Series. The bayonet style thermowell is sometimes used with metal, koramic, glass and quartz face heaters to measure the actual face temperature (emitting surface) as opposed to the heating element temperature. The thermocouple goes through a bayonet fitting and is compressed using a stainless steel spring. This approach assures that the tip of the thermocouple makes correct contact with the heater face.

The bayonet style thermowell is sometimes used with metal, koramic, glass and quartz face heaters to measure the actual face temperature (emitting surface) as opposed to the heating element temperature. The thermocouple goes through a bayonet fitting and is compressed using a stainless steel spring. This approach assures that the tip of the thermocouple makes correct contact with the heater face. It is becoming more common for equipment manufacturers and end users to make use of optical pyrometers, or non-contact thermometers, to sense product temperature as opposed to heater temperature. In virtually all applications, product temperature is the temperature of choice. Heater temperature is only used as a reference in order to attain a particular product temperature. The reduced price for these devices and the quest for better process control has driven the use of optical pyrometers. For that reason, it is sometimes necessary to provide an opening (1.5″ – 2″ (38 – 51 mm) diameter hole) through the heater where the optical pyrometer can be placed to monitor the product temperature. The pyrometer hole size can vary based on the specific requirements. A smaller hole is always preferred to avoid nonuniform heating of the product.

It is becoming more common for equipment manufacturers and end users to make use of optical pyrometers, or non-contact thermometers, to sense product temperature as opposed to heater temperature. In virtually all applications, product temperature is the temperature of choice. Heater temperature is only used as a reference in order to attain a particular product temperature. The reduced price for these devices and the quest for better process control has driven the use of optical pyrometers. For that reason, it is sometimes necessary to provide an opening (1.5″ – 2″ (38 – 51 mm) diameter hole) through the heater where the optical pyrometer can be placed to monitor the product temperature. The pyrometer hole size can vary based on the specific requirements. A smaller hole is always preferred to avoid nonuniform heating of the product. The flag type terminal consists of a flat piece of stainless steel that is .350″ (8.9mm) wide x .032″ (0.81mm) thick with a .187″ (4.75mm) hole near the end. This is our preferred termination because of the excellent electrical contact that is achieved with this type of connection. All of the electrical terminal options are typically housed within a 2″ x 4″ (51mm x 101.6 mm) or 4″ x 4″ (101.6 mm x 101.6 mm) electrical box.

The flag type terminal consists of a flat piece of stainless steel that is .350″ (8.9mm) wide x .032″ (0.81mm) thick with a .187″ (4.75mm) hole near the end. This is our preferred termination because of the excellent electrical contact that is achieved with this type of connection. All of the electrical terminal options are typically housed within a 2″ x 4″ (51mm x 101.6 mm) or 4″ x 4″ (101.6 mm x 101.6 mm) electrical box. The stud type terminal consists of a threaded stud that exits the heater for an electrical connection. A number of different connection lengths and stud sizes are available. The disadvantage of a stud type terminal is the electrical current limit of the stud. An electrical current is only carried on the threads of the stud.

The stud type terminal consists of a threaded stud that exits the heater for an electrical connection. A number of different connection lengths and stud sizes are available. The disadvantage of a stud type terminal is the electrical current limit of the stud. An electrical current is only carried on the threads of the stud. Another version of this connection is the ceramic block flag type terminal. This design makes use of a flag type terminal exiting the heater that is bent over a ceramic mounting block with a vertically mounted stud. This approach uses the stud as a means of easy connection but not as a current-carrying device. Therefore, higher current can be carried through the electrical connection. This type of connection is not available on all heaters.

Another version of this connection is the ceramic block flag type terminal. This design makes use of a flag type terminal exiting the heater that is bent over a ceramic mounting block with a vertically mounted stud. This approach uses the stud as a means of easy connection but not as a current-carrying device. Therefore, higher current can be carried through the electrical connection. This type of connection is not available on all heaters. Wire leads is a fourth termination option available on Solar Products’ heaters. This option is only available on heaters having a watt density lower than 10 watts per square inch (15.5 kW/m2). A high-temperature wire is resistance welded to an intermediate piece of stainless steel, and the steel piece is in turn resistance welded to the heating element. The wire leads can be fabricated in any required length.

Wire leads is a fourth termination option available on Solar Products’ heaters. This option is only available on heaters having a watt density lower than 10 watts per square inch (15.5 kW/m2). A high-temperature wire is resistance welded to an intermediate piece of stainless steel, and the steel piece is in turn resistance welded to the heating element. The wire leads can be fabricated in any required length.