T-Series Quartz Tubes

T-Series quartz tubes are available in a multitude of different customizable configurations.

Configurations

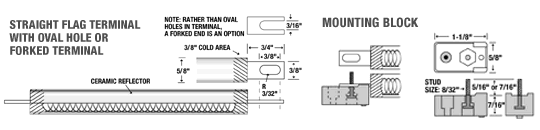

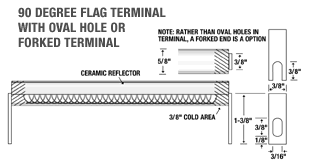

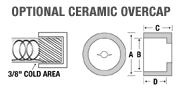

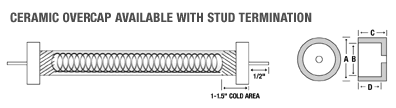

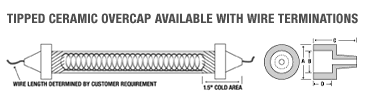

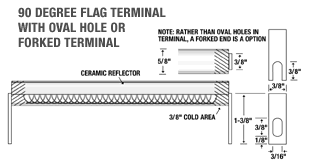

The quartz tubing can be constructed as either clear or translucent, and the tube’s coils can be produced as standard or fast response. Their terminations are manufactured as flag type, stud type, wire leads, wire terminal, quick disconnect, fuse type or single-ended type. Our quartz tubes are available with no reflector, an internal ceramic reflector or a gold-backed reflector. The tubes’ watt density can be done up to 60 watts/lineal inch, and the tubes have a maximum length of 90″. They can be pre-assembled into a fixture or purchased individually.

Tubes vs. Lamps

Quartz tubes and quartz lamps are often thought to be interchangeable terms. However, this is actually not true. A chart comparing their differences is shown below:

| Comparative Points | Quartz Lamps (T3) | Quartz Tubes |

|---|---|---|

| Color Sensitivity — the effect product color has on heating cycle times | Yes (Example: white-colored products will take longer to heat than black) | Minimal |

| Wavelength | Primarily short-wave | Primarily medium-wave |

| Type of element | Tungsten filament in a vacuum (Usually an inert gas, such as argon is used) | Iron-Chromium-Aluminum element (Nickel-Chromium is also used) |

| Power output per tube | Up to 200 watts/lineal inch | Up to 60 watts/lineal inch |

| Power output over a given area | Up to 60 watts/in2 is common | Up to 60 watts/in2 |

| Power switch device | Expensive phase-angle SCR | Reasonably priced zero-cross SCR or SSR |

| Temperature response | Up to temperature in 2-4 seconds Up to color in 1-2 seconds |

Up to temperature in 5-30 seconds, depending on the design |

| Inrush current | 700% – 1000% | 7% initial current |

| Terminal cooling requirements | Air or water cooling required | No cooling requirements |

| Design flexibility | Standard sizes available | Custom manufactured in length, wattage, voltage and termination |

| Typical life expectancy | <5,000 Hours | 10,000 Hours |

Clear Tubing

![]() For most applications, clear tubing is the preferred choice. Because clear quartz has a much higher transmission rate of infrared energy than translucent quartz, it also has a higher radiant efficiency.

For most applications, clear tubing is the preferred choice. Because clear quartz has a much higher transmission rate of infrared energy than translucent quartz, it also has a higher radiant efficiency.

In addition, clear quartz provides for a faster response time and generates a shorter wavelength than translucent quartz. It is available in a larger number of diameter options and can operate at higher temperatures — namely up to 1800°F (982°C).

Translucent Tubing

![]() The main advantages of translucent tubing are low pricing, longer wavelength, and a non-exposed heating element. Some customers prefer a translucent tube for their applications for the aesthetic reason that the heating element is concealed within the tube.

The main advantages of translucent tubing are low pricing, longer wavelength, and a non-exposed heating element. Some customers prefer a translucent tube for their applications for the aesthetic reason that the heating element is concealed within the tube.

Tubing Diameter

Clear- 3/8″, 1/2″, 5/8″, 7/8″ and 1″ | Translucent- 3/8″, 1/2″ and 5/8″.

The tubing diameter is commonly determined by matching the existing tube diameter or by basing it on the specifics of the tube’s design using aspects such as wattage, voltage and heated tube length. The goal is to maintain a low coil watt density for a long tube life. Coil watt density should not be confused with watts per lineal inch, which is the total wattage divided by the heated length. Coil watt density is the watt density on the coil itself. A good design for long element life is attained by having a low coil watt density. Sometimes this is accomplished by changing the tube voltage, while other times the tube’s diameter is increased.

In addition, clear quartz provides for a faster response time and generates a shorter wavelength than translucent quartz. It is available in a larger number of diameter options and can operate at higher temperatures — namely up to 1800°F (982°C).

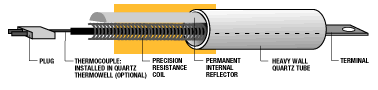

This heating element is a single precision-wound resistance wire made of an iron-chromium-aluminum alloy. The heating element typically gets up to temperature in 10 – 20 seconds depending on tube design. This coil has a typical life expectancy of 10,000 hours and a maximum watt density of 60 watts per lineal inch.

This heating element is a single precision-wound resistance wire made of an iron-chromium-aluminum alloy. The heating element typically gets up to temperature in 10 – 20 seconds depending on tube design. This coil has a typical life expectancy of 10,000 hours and a maximum watt density of 60 watts per lineal inch. This patented heating element has two intertwined precision-wound resistance wires made of iron-chromium-aluminum alloy wire. By reducing the wire’s mass, the time required for the element to get up to temperature is greatly reduced. The multiwound element is up to operating temperature in five seconds. The actual time will depend, however, on the overall design of the tube. This coil has a typical life expectancy of 5,000 hours and a maximum watt density of 60 watts per lineal inch.

This patented heating element has two intertwined precision-wound resistance wires made of iron-chromium-aluminum alloy wire. By reducing the wire’s mass, the time required for the element to get up to temperature is greatly reduced. The multiwound element is up to operating temperature in five seconds. The actual time will depend, however, on the overall design of the tube. This coil has a typical life expectancy of 5,000 hours and a maximum watt density of 60 watts per lineal inch.