V Series Heaters

Offers power densities and response time that rival short wavelength heaters.

Fast Response Medium Wavelength Infrared Panel Heaters

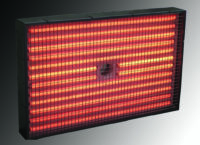

Introducing the revolutionary V-series heater. The V-series is perfect for applications that require high power, tight process control and fast heat-up/ cool-down. V-Shaped stamped elements have low mass for fast heating/cooling and minimal thermal lag for extremely tight process control. The elements are bonded to a high temperature insulation board having low thermal conductivity, low thermal mass and low heat capacity to minimize stored heat so they can be switched on and off in seconds. This makes them ideal for processing heat sensitive products such as coated webs and textiles. V-series heaters offer power densities and response times that rival those of short wavelength heaters except they come in a very durable construction and have a medium wavelength output, which is readily absorbed by most products. Therefore, they are ideally suited for drying water or solvents as well as heating plastics, glass, etc.

Optional Back-mounted fans

Optional Pyrometer view port through heater.

Optional Parallelogram modules for zoning across wide webs.

Benefits

The unique V-shaped element provides numerous performance improvements over conventional stamped element heaters including the following:

- Reduced cost

- Faster heat-up and cool-down

- Higher watt density

- Reduced thermal back-losses

- More robust construction (no need for special handling or shipping)

- More freely radiating design

- Longer life

- Elimination of hot spots

- Improved heating uniformity

Standard Features

- Element temperatures up to 2,100° F (2 micron peak wavelength)

- Typical life expectancy of 12,000+ hours, depending on temperature

- Heater wattages up to 100 watts per square inch

- Can be operated in any plane without any element sag or “coil creep”

- Stainless steel screen protects face

- Maintenance free

- Various voltages up to 600V

- Superior mechanical strength

- ¹/4 -20 mounting studs

- Electrical junction box

Optional Features:

- Replaceable type K thermocouple

- Air holes for extremely fast cool down and/or to provide scrubbing action in drying applications

- Pre-mounted fans

- Multi-zone heaters

- Pyrometer view port through heater

- Stainless steel housing

- No housing (heater board only)

- Wire leads

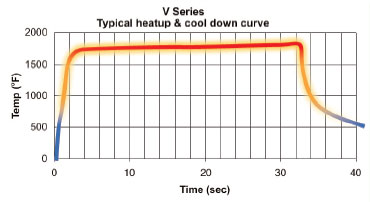

V-Series Warm-up Curve

- V Series vs. The Competition

- Reduced Thermal Back Losses & Increased Radiant Efficiency

- Increased Strength

- Higher Power, Longer Life

- Summary of Benefits

V Series vs. The Competition

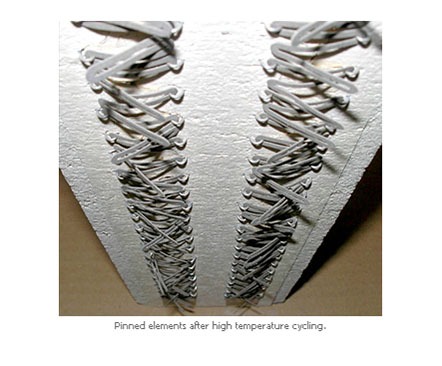

Fast-responding, medium-wavelength, infrared panel heaters using stamped serpentine elements have been used in industry for decades. In traditional construction, the flat elements are held against a refractory board by manually inserted pins. Solar Products Inc. has developed a unique V-shaped element which provides numerous performance improvements over conventional stamped element heaters including the following:

- Reduced thermal back-losses

- Higher watt density

- More robust construction

- More freely radiating design

- Longer life

- Elimination of hot spots

- Improved heating uniformity

- Lower cost

According to Paul Ross, VP of Product Development “…Solar Products didn’t invent the stamped element heater, but we certainly perfected it…”

Recently, Solar Products pitted their V Series heater against the competition in a head-to-head comparison.

Solar Products built a V series heater to closely match a sample heater from a leading competitor. Both heaters were 4.25” x 13.75” with (2) elements of 11” heated length. The competition used 0.135” thick elements and Solar used its closest match, 0.139” thick. To compensate for the slight difference in resistance, the voltage was adjusted so that each heater produced the same total wattage of 1,481W